SPI Products Let the Rain Drain While the Oil’s Contained

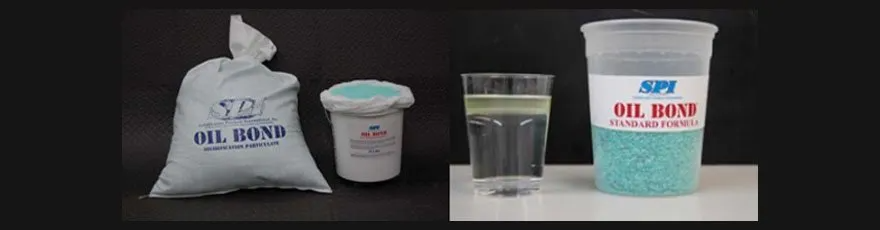

Solidification Products International is an industry leader in products that control spills, leaks, and other oil-control issues. For over 30 years, our locally owned and veteran-owned small business has helped businesses comply with environmental protection laws. Call today for a free consultation.

CONTACT US