Solidification Products International Inc. offers Petro-Barriers™ for 100% oil containment in large areas. Petro-Barriers are designed for the largest volume of water drainage. This oil barrier functions in a good drainage containment area with vertical installation. All Petro-Barriers are custom-designed and manufactured at the SPI factory and delivered to your facility.

Large Containment Area Stormwater Drainage Filter

When designing these complete oil containment systems, factors like land slope, under-drain percolation rates, rainfall amount and containment area size influence the final product. SPI can manufacture solutions capable of draining over 30 gallons of water per minute while trapping oil in three layers of filter material.

Setups with Petro-Barriers vary widely. Large containment areas or wet climates may require six or more systems, while smaller areas may only need two. The experienced team at Solidification Products International Inc. leads the customization process to create the ideal system.

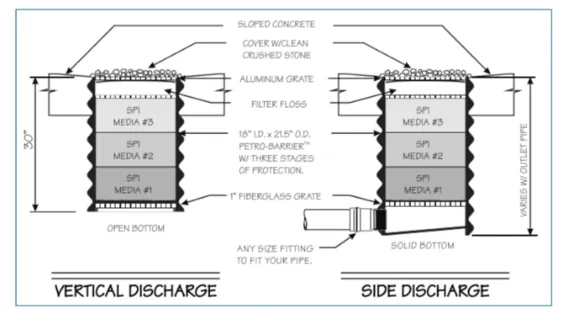

The original Petro-Barrier design uses a sump in a containment area. The bottom 20 inches is filled with crushed stone to discharge rainwater and the top 4 inches are dirt and debris filters that can be replaced for system maintenance.

In a spill containment area surrounding an oil storage vessel or oil-filled electrical transformer, the ground is designed to resist oil and water. The ground is sloped to drainage sumps where the Petro-Barriers are installed. After creating the drainage path, SPI fills the drainage sumps with three types of media that allow water to pass while removing and containing oil. One filters oil sheen, one is an active absorption media, and the third media is the most active product for oil and water separation.

Benefits of Petro-Barrier

With the Petro-Barrier, facilities can benefit from:

- 100% oil containment

- Support for high-volume water

- Slope compatibility

- Rainwater discharging

- Oil sealing

- Compatibility with poorly drained areas

- Customization by working with the SPI team

Applications of Petro-Barrier

Petro-Barriers have many applications.

In a Transformer Oil Containment Area

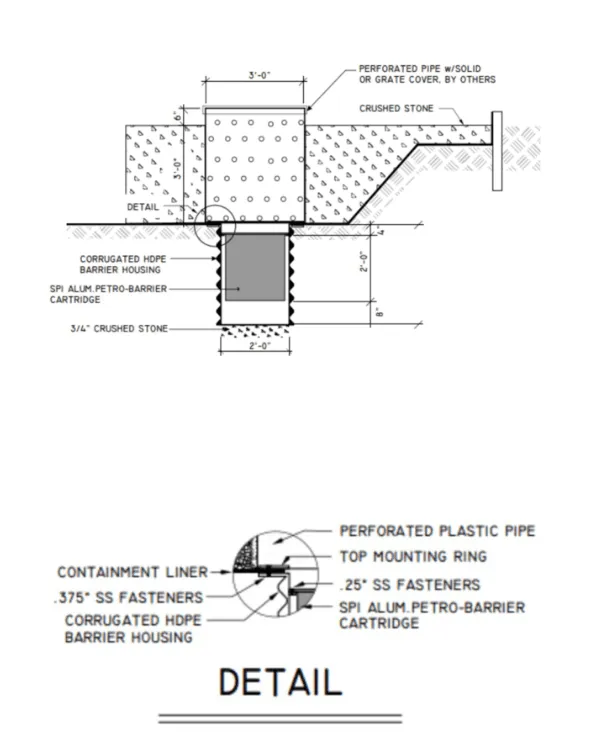

Transformer oil containment areas can vary, and Petro-Barrier will adapt for 100% oil containment. For example, a Petro-Barrier setup may feature a perforated drain pipe underneath with a crushed stone surround. This design allows for rainwater to drain and dissipate into the ground for poorly draining clay-like soils.

Another type of setup may use a concrete moat system with four Petro-Barriers in each corner. Steel grates above create a level work surface around the transformer, while top hat filters protect the Petro-Barrier from dirt and debris.

For New Installations and Replacements

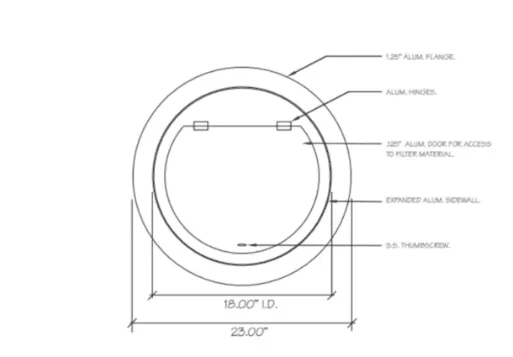

The Petro-Barrier is available in various sizes to work for a wide range of existing sumps. The system features a canister that has two flanges for easy removal when maintaining or replacing your system.

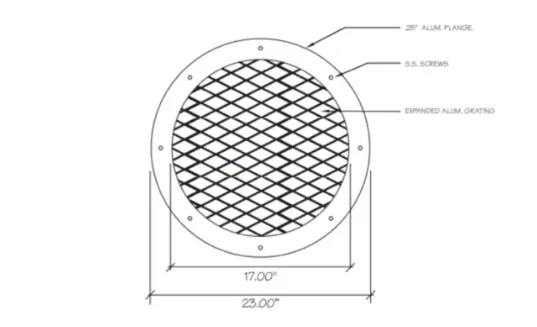

The area must be cleaned of dirt and debris, and the canister must be attached with a bead of industrial sealant. A top hat filter basket is attached to the canister to keep debris out.

Prefab Petro-Barriers

Prefabricated Petro-Barriers are made to discharge directly into the ground. SPI can also incorporate lateral discharge to a dry well or daylight. These prefab Petro-Barriers feature our three layers of media to offer 100% oil spill protection.

Installation for prefab Petro-Barriers varies based on need. Some may be installed in existing storm drains, while others are installed through containment liners.

Case Studies

A facility relied on our prefab Petro-Barriers during the installation of a new transformer. The prefab Petro-Barriers were installed during the construction process.

At a hydro facility, Petro-Barriers prevented oil spills at a hydro dam. Pre-filter canisters are attached with hinged tops to simplify maintenance.

Choose SPI for Water Drainage Products

Get in touch with us today to get a quote for Petro-Barrier systems.

Contact Us