SPI Pump-Thru Barriers Offer Versatile Applications

Solidification Products International Inc. is a leader in oil protection products for rainwater, and the Pump-Thru Barrier™ exemplifies our commitment to high-performance products. With the SPI Pump-Thru Barrier, facilities can keep rainwater clean in any containment area without installing systems during construction. Explore the full benefits of this system.

The blue cylindrical pre-filter, a sump pump with a heating ring and the new custom-made heating blanket, are all new additions to the Pump-Thru Barriers overall versatility. The pre-filter canister itself has dramatically improved the longevity of the internal dirt filters built into the units.

High Volume Rainwater Drainage For Secondary Containment

The SPI Pump-Thru Barrier is a portable containment unit for the rapid removal of rainwater in high volumes. The Pump-Thru Barrier uses a sump pump with SPI-patented media for efficient hydrocarbon removal. Rainwater is pumped in the Pump-Thru Barrier and passively drains as the media removes the oil sheen. In the event of an oil spill, the unit seals off completely to contain the spill.

Pump-Thru Barriers feature an internal filter that cleans rainwater before reaching the media. During a spill, oils are diverted to a return system that flows back to the containment area. Overflow directs back to the containment area until the sump pump is turned off. In rainstorms, the rainwater pumps into a portable Pump-Thru Barrier with dirt and oil sheen filters that prevent clogs. These filters can be quickly replaced.

In colder climates, Pump-Thru Barriers have thermal heating blankets to protect the unit housing and the external water filter. An additional sump pump pre-filter can also be used and cleaned as needed.

The Pump-Thru Barrier is best used in containment areas where you need assurance that no oil sheen will discharge.

Benefits of Pump-Thru Barrier

Facilities that choose the Pump-Thru Barrier can experience:

- 100% fuel and oil protection

- 24/7/365 operation

- Oil sheen removal to less than 3 parts per million (ppm) or non-detectable levels

- Rainwater drainage

- Reduced manual pumping following spills

- Fast and easy filter replacement

Applications and Maintenance of Pump-Thru Barrier

Pump-Thru Barriers are capable of removing many types of fuels, including:

- Diesel

- Transformer oil

- Heating oil

- Jet fuel

- Kerosene

- Gasoline & crude oils

- Hydraulic oil

- Other hydrocarbons

Pump-Thru-Barrier Oil and Water Separator

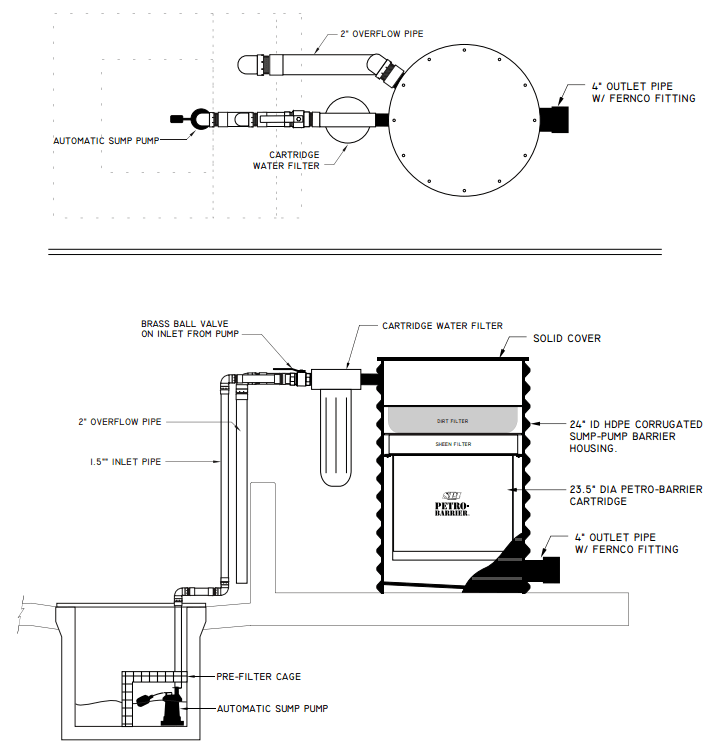

The SPI Pump-Thru-Barrier is outfitted onsite with an external water filter and support brace. The external filter removes dirt down to 35 micros and allows the system to capture the fine dirt prior to getting into the internal dirt filters.

The sump pump is turned on and the flow is adjusted with a max flow rate on the 24” unit of 35 gpm.

Cold Weather Operation of the Pump-Thru-Barrier

Our custom heating blankets have been tested for temperatures below -40 degrees in extreme conditions. Our custom heating blankets allow for safe oil containment in freezing temperatures. Learn more about our cold weather oil containment solutions.

Drawings

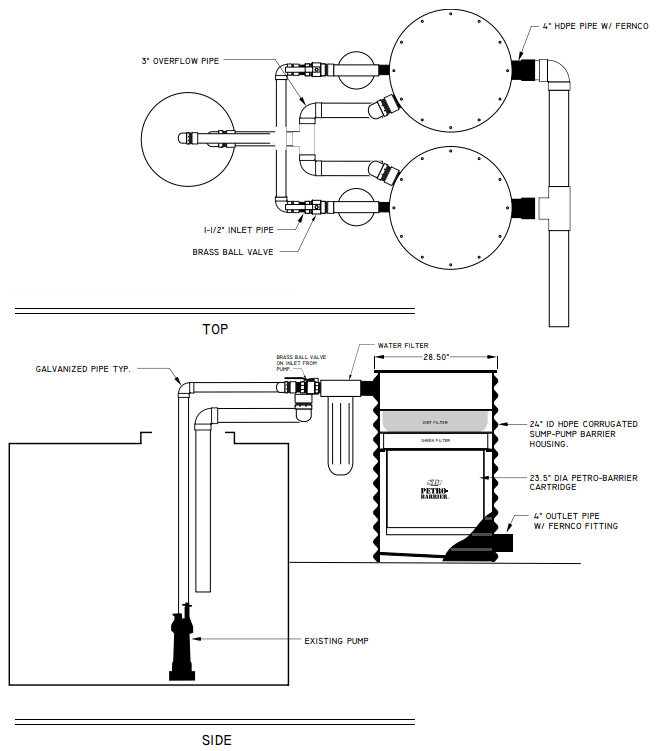

See a detailed image of the Pump-Thru Barrier setup.

Pump-Thru Barrier Drawing

Dual Installation – Pump-Thru Barrier

Discounted Quotes for U.S. Government & Military

Our patented Pump-Thru Barriers are essential oil containment solutions for the government and military. Government agencies and authorized personnel can receive federal purchasing assistance when requesting a quote.

Trust SPI for Oil Containment Barriers

SPI specializes in a range of oil containment systems that offer impressive oil separation and removal of rainwater. With the ability to reduce manual pumping during oil spills, operations can improve oil containment efficiency and prevent costly fines for water contamination. Get in touch with us today to learn more about the Pump-Thru Barrier and our other SPI products.